BioProfile® Basic, 100, 300, 400, pHOx:

BioProfile® Basic, 100, 300, 400, pHOx:

BioProfile Chemistry Analyzers for Mammalian Cell Culture

Nova BioProfile analyzers include four models of fully automated cell culture analyzers with test menus of two to ten tests, including chemistry, gases, and electrolytes. Each model offers automatic calibration, one-button operation, and 40 position batch processing capability.

- Six models and test menus

- All results available in 3 minutes or less

- Automatic one-button operation

- 40-position batch processing capability

- Automatic analyzer calibration

- No external sample dilutions

- No gas tanks required

| Model | Test/Menu |

|---|---|

| BioProfile Basic 2 | Glucose, Lactate |

| BioProfile Basic 4 | Glutamine, Glutamate, Glucose, Lactate |

| Model | Nutrients/Metabolites | Acid/Base Status | Electrolytes | Calculated Parameter |

|---|---|---|---|---|

| BioProfile 100 Plus | Glutamine, Glutamate, Glucose, Lactate, Ammonium | pH | Sodium, Potassium | Osmolality |

| BioProfile 400 | Glutamine, Glutamate, Glucose, Lactate, Ammonium | pH, PO2, PCO2 | Sodium, Potassium | Osmolality, Air Saturation, CO2, Saturation, HCO3 |

BioProfile Analyzers for Bacterial Fermentation

BioProfile 300A and 300B offer glucose, lactate, acetate, ammonium, pH, sodium, potassium and a choice of either phosphate or glycerol. These systems offer measurement ranges specifically suited to bacterial fermentation. Both models feature automatic calibration, one-button analysis and batch processing capability

| Model | Nutrients/Metabolites | Acid/Base Status | Electrolytes | Calculated Parameter |

|---|---|---|---|---|

| BioProfile 300 A | Glucose, Lactate, Ammonium, Acetate, Phosphate* | pH | Sodium, Potassium | Osmolality |

| BioProfile 300 B | Glucose, Lactate, Ammonium, Acetate, Glycerol | pH | Sodium, Potassium | Osmolality |

* Also reports phosphorus

BioProfile Applications

Developed in conjunction with leading biotechnology companies, BioProfile analyzers provide the chemistry assays necessary to address the testing requirements of small to large scale bioprocessing, encompassing:

- Research and Development

- Process Development

- Pilot Plant

- Production

Applications of the BioProfile include:

- Monitoring the progress of bioreactor runs

- Determining the consumption and production of key metabolites

- Identification of growth-limiting nutrients

- Design of feeding strategies

- Calibration of bioreactor probes

- Measurement of cellular respiration

- Balancing media electrolytes

- Control levels of waste product

Time/Labor Savings

BioProfile’s comprehensive test menus allow consolidation of testing into a single analyzer. This results in significant time and labor savings, as well as real-time process control capabilities.

BioProfile’s fast analysis time and consolidated testing offer the following advantages:

- Eliminate the requirement for taking multiple samples and large sample volumes from reactor vessels

- Provide real-time access to test results, enabling real-time process control

- Substantially decrease labor, capital equipment, and reagent costs

- Improve the ability to effectively monitor and control bioreactor processes

- Improve process reliability and reproducibility

- Speed optimization of feeding strategies

- Improve manufacturing yield and quality bioprofile analysis time

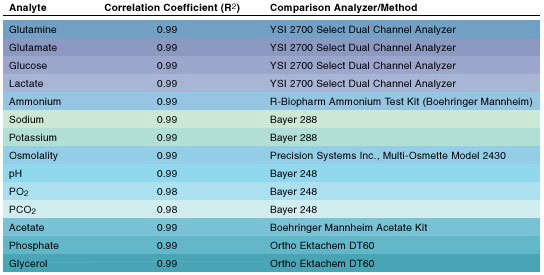

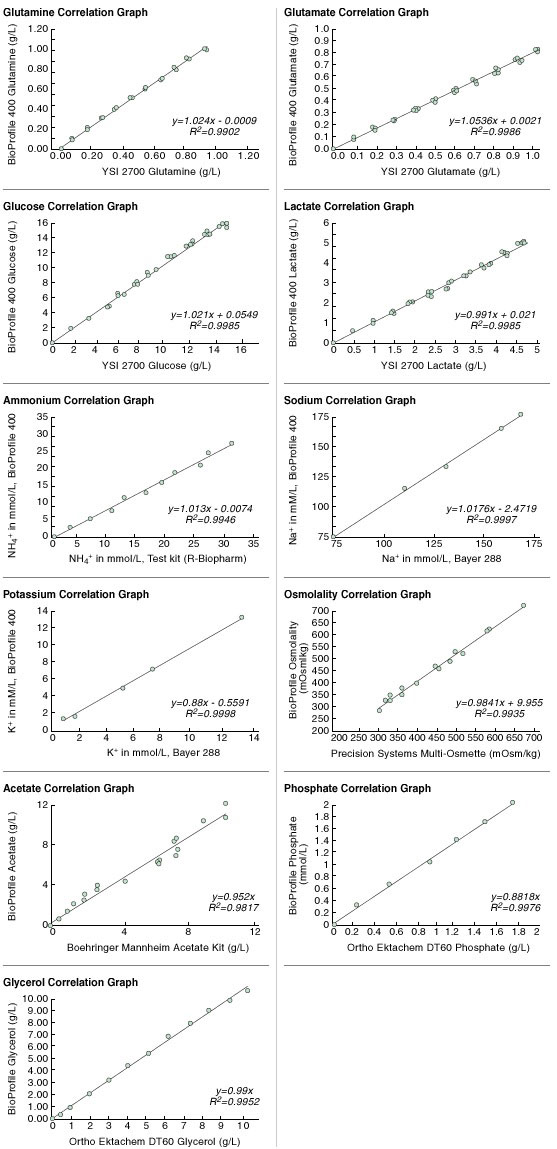

Analytical Performance

Unlike in-situ monitoring devices, BioProfile Analyzers automated calibration protocol provides precise quality control and maintains consistency of test results. BioProfile’s automated measurement provides faster, more accurate results than off-line methods.

Results obtained from BioProfile show excellent correlation with conventional techniques.

Correlation Data

Automated Testing

Automated Testing

Fully-Automated Testing

BioProfile Analyzers are fully automated and designed for easy use by any operator. After the “ANALYZE” key is pressed, the sample is automatically aspirated, and the analysis is performed without further operator intervention. An on-board computer monitors the analysis cycle from sample aspiration to results presentation. The operational status of the BioProfile Analyzer is continuously displayed; any deviation from normal operation is promptly reported to the operator with any suspect data flagged.

Batch Processing

Batch Processing

Automated Batch Processing

BioProfile Basic, 100 Plus, 300 and 400 offer a 40-position sample tray that enables batch processing with full walkaway automation. The sample tray will accommodate a variety of tube sizes including:

- 500 µL – 2 mL Eppendorf tubes

- 500 µL – 4 mL sample cups

- 5 mL – 7 mL test tubes

- A complete 40-sample tray can be analyzed in approximately 80 minutes

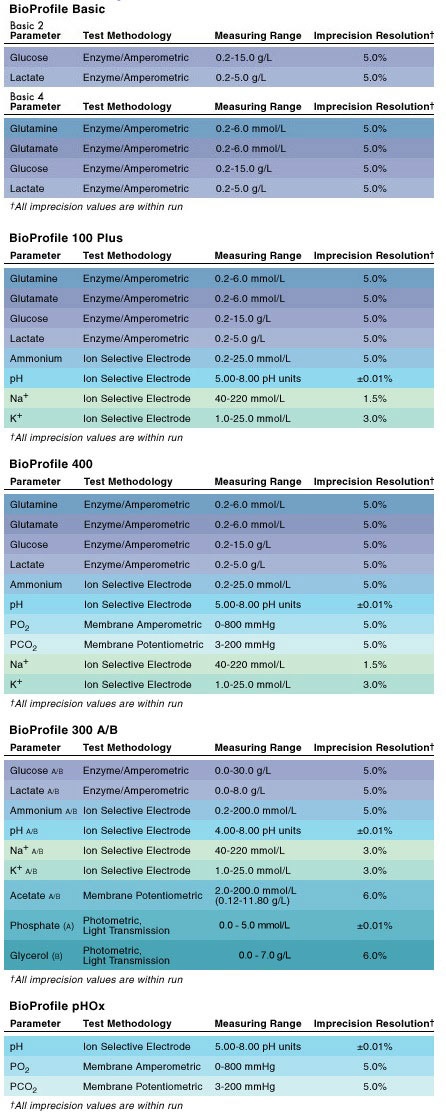

Measurement Ranges

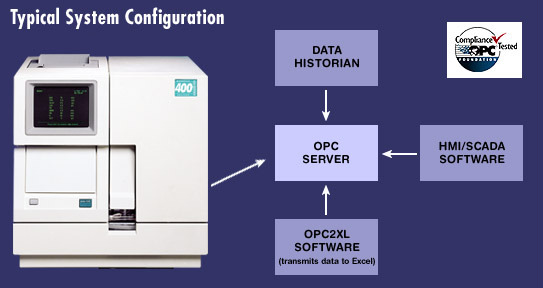

OPC Server

Nova’s OPC Server software allows BioProfile to transfer analytical data on key chemistries to any bioreactor controlling software that is OPC compliant. This critical data allows the controller to initiate real-time feedback control to optimize the bioprocess. The OPC Server software can be installed on the Nova Biomedical Data Manager (BDM) or on an ancillary computer.

OPC is a published industrial standard for system interconnectivity that provides a standards-based infrastructure for the exchange of process control data. It uses Microsoft COM and DCOM technology to enable applications to exchange data on one or more computers using client server architecture.

OPC defines a common set of interfaces so that each application retrieves data in exactly the same format, regardless of the data source. Using OPC standards, data can be transmitted from any data source to any OPC-compliant application including HMI/SCADA, data historians, spreadsheets, and databases. The result is a complete, out-of-the-box, plug-and-play communication solution.

True interoperability reduces implementation costs and builds a fully scaleable system to accommodate your current and future bioprocessing requirements.

21 CFR Part 11 Compliance

21 CFR Part 11 describes regulatory requirements governing electronic signatures and records that assure the integrity of data from an analytical instrument such as BioProfile.

The BioProfile Data Management System (BDM) incorporates an effective data archive and restoration system as well as adequate security features and audit trails to automatically monitor the creation, modification, and deletion of electronic records. These features create full compliance with 21 CFR Part 11 requirements.

IQ/OQ

The BioProfile Instrumentation Qualification (IQ) protocol provides comprehensive information to assist in validating the BioProfile Analyzer for use in your bioprocess.

The IQ protocol includes:

- System documentation

- Pre-installation checks

- Installation procedure checks

- Installation performance qualification

- Instrument/system control verification

The BioProfile Instrumentation Qualification/Operation Qualification (IQ/OQ) service includes all Installation Qualification procedures outlined above, plus:

- Performance of IQ/OQ procedures

- All required NIST traceable standard materials

- Statistical analysis and final report

These optional services can be performed either during installation or at a later date

Certifications & Compliance: ISO 13485:2003 Quality System Registration, IVDD, Meets IEC 61010, UL, CSA Standards FDA Labeling: For in-vitro diagnostic use. Patented Technology. Patents 6,287,451 / 6,837,976 / EP 1 212 609 / CA 2,375,092 / EP 1497 449 / JP 405 0078 Specifications subject to change without notice.