BioProfile® FLEX2 Basic

Automated Cell Culture Chemistry Analyzer

Automated Cell Culture Chemistry Analyzer

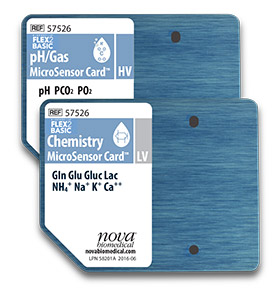

FLEX2 Basic utilizes Nova’s groundbreaking MicroSensor Card™ technology to provide a fully automated cell culture analyzer that eliminates biosensor maintenance, increases analyzer speed, and reduces sample volume. The full 11-test cell culture menu includes: Gluc, Lac, Gln, Glu, NH4+, Na+, K+, Ca++, pH, PCO2, PO2

Simple touchscreen operation, a choice of sampling modes, fast analysis time, and automated quality control (QC) provide simplicity, labor savings, and workflow efficiency for cell culture optimization and monitoring.

Maintenance-free chemistry and gas sensors

Chemistry and gas sensors

are combined in the credit-card-sized MicroSensor cards, which use proven Nova biosensor technology that has been validated in thousands of cell culture processes. Cards are maintenance free, have a minimum use life of 21 days, and are replaceable in seconds.

Chemistry and gas sensors

are combined in the credit-card-sized MicroSensor cards, which use proven Nova biosensor technology that has been validated in thousands of cell culture processes. Cards are maintenance free, have a minimum use life of 21 days, and are replaceable in seconds.

Fast analysis time

Test results for the complete menu are available in less than 2 minutes. This is the highest throughput of any cell culture analyzer and allows a fully automated batch analysis of a 96-well microtiter plate in just over 3 hours. FLEX2 Basic has a maximum daily throughput of 700+ samples per day.Small sample volume

Sample volume is 265 μL for a full 11-test profile, enabling chemistry testing from virtually all sizes of cell culture systems.Onboard automated QC

Onboard liquid QC provides true verification of performance and saves hours of labor each week compared to manual QC testing. QC cartridges contain up to a 30-day supply of QC material. Controls are run automatically at user-selected intervals.

Intuitive user interface with touchscreen display

- The color touchscreen is easily operated with intuitive prompts and requires minimal training.

- The most commonly used function screens can be navigated with a single click.

- Batch assignment of sample information and test panels makes programming 96-well plates and sample trays fast and eliminates errors in setup.

Cartridge-based reagent management system (RMS)

RMS reagent cartridges provide several advantages.- Cartridge installation date, time, and lot number data are automatically recorded.

- Reagent usage and expiration are monitored.

- A self-contained, closed waste receptacle within the cartridge eliminates direct handling of waste and contact with hazardous biological materials. Other systems can pose significant waste handling hazards to operators.

Automated 96-well microtiter plate analysis

Syringe or cup sampling for critical analysis

Individual samples also can be analyzed directly from syringes or cups. Batch sampling 96-well plates can be interrupted at any time to run critical samples.

Advanced Analytical Technology

The FLEX2 Basic test menu is configured with advanced chemistry and gas analysis technology that is integrated with robotics. The state-of-the-art technology has been proven and characterized in hundreds of cell culture processes.Chemistries by electrochemistry

Glucose, lactate, glutamine, glutamate, ammonium, sodium, potassium, and calcium measurements are performed using electrochemical biosensors integrated into one credit-card-sized component.

Broad analytical range with improved low end accuracy

The lower analytical range has been extended to provide accurate results down to 0.10 g/L for glucose/lactate and 0.10 mmol/L for glutamine/glutamate.

An external load-and-go sample tray allows for continuous loading of cell culture samples for the most flexible and efficient sample throughput.

Onboard auto-dilutions

Robotic automation and a precise metering syringe perform all dilutions on board, eliminating

time-intensive manual dilutions and error associated with manual techniques. The use of onboard

auto-dilutions provides the broadest analytical

range of any cell culture analyzer.

Chemistries are unaffected by cell concentration

Photometric detection methods used by other analyzers often require time-consuming, manual pre-dilution of high cell concentration samples to avoid poor measurement accuracy. FLEX2 Basic provides accurate results regardless of cell concentration.

Analyte specificity

Nova’s biosensors are developed specifically for cell culture applications, where processes typically utilize extremely complex media formulations. These electrochemistry detection methods provide excellent specificity for the analyte of interest.

High throughput chemistry analysis

FLEX2 Basic is capable of analyzing a full chemistry panel using 135 µL of sample in 120 seconds, or a throughput of 30 samples per hour. Full 96-well plates can be analyzed in about three hours.

Gases by amperometry, potentiometry

pH, PCO2, and PO2 measurements are performed by potentiometric and amperometric biosensors. Biosensors are located in the maintenance-free, disposable MicroSensor Card.

Improved accuracy

Unlike hospital blood gas analyzers, which are often used for cell culture analysis, Nova’s algorithms for measuring pH, PCO2, and PO2 were specifically developed for cell culture applications. These algorithms are optimized for mammalian cultures, which typically exhibit much higher oxygen consumption and carbon dioxide production rates compared to human blood cells. FLEX2 Basic ensures accurate pH and gas values even in cultures with high cell densities.

Gas and pH values available in manual and 96-well plate analysis modes

The user can configure FLEX2 Basic to provide gas and pH results from both manual samples and 96-well microtiter plate samples.

Connectivity and Compliance

Advanced OPC connectivity

Nova’s OPC connectivity integrates with any OPC-compliant devices, such as bioreactor controllers, data historians, laboratory information management systems (LIMS), and plant management systems. Nova’s OPC connectivity features:- Automated bidirectional data and control commands

- Data archiving

- Connection to any OPC-compliant device

- Connectivity verification

- Bioreactor feedback control

- Remote monitoring of status and data

USB and network printing

Sample data, QC results, and all audit and calibration logs can be sent to both external USB printers as well as network printers.Compliance with 21 CFR Part 11

Limited accessUser log-on is secured by both user ID and password. Automatic log-off features prevent unauthorized access.

Electronic record retention and retrieval

- All data are securely retained through password access control in both human-readable and electronic forms.

- Records are readily retrievable throughout their retention period.

Audit trails

- Time-stamped audit trails record the date and time of operator entries and actions that create, modify, or delete electronic records.

- Record changes do not obscure previously recorded information.

- Records are maintained in original and audited form.

GMP compliance

FLEX2 Basic meets GMP manufacturing requirements through installation qualification (IQ) and operational qualification (OQ) documentation and validation support from Nova specialists.

Support Services

The purchase of a FLEX2 Basic analyzer is just the beginning of a long commitment from Nova to you. Nova offers an extensive array of support services to help maintain peak analyzer performance.

Installation

Performed by a Nova field specialist, installation consists of analyzer setup and performance verification.Validation assistance

Nova installation staff can perform extended precision and reference analyzer correlation studies. Nova performs all tests and provides complete documentation to verify compliance to regulatory standards. In addition to IQ/OQ support, we can assist with performance qualification (PQ) protocol development and implementation.Field service

On those occasions when service is needed, a team of field service representatives, located throughout the country, is available to provide on-site support, resolving issues with minimal downtime.

Comprehensive applications support

A knowledgeable applications staff with significant industry experience is available to help with custom optimizations, IQ/OQ, process automation support, and other site-specific needs.Telephone assistance hotline

We maintain a highly skilled and experienced technical support staff available by phone or email. From basic questions to advanced troubleshooting, they are able to resolve most problems over the phone without requiring on-site support.

ノバ・バイオメディカル株式会社 電話: 03-5418-4141 メール: jp-info@novabio.com

Specifications

11-test cell culture analyzer

Sample Analysis Time: 2.0 minutes (Chemistry only), 2.0 minutes (Gas only), 2.0 minutes (All tests)

Operating Temperature Range:10–30oC (50–86oF)

Operating Relative Humidity Range: 20–85%

Sample Size: 135 to 265 µL

Sample Options: Individual via syringe/cup

Automated batch using 20-position tray or 96-well plates

Operating System: Windows 10

Electrical Requirements: 90-264 VAC, 50 to 60 Hz

(Universal Power Supply)

System Size: Height: 24 in (61 cm), Width: 17 in (43 cm), Depth: 25 in (64 cm)

System Weight: 94 lb (42.6 kg) without reagent packs

Safety Certifications: IEC 61010-1:2001, Quality Systems Certification:

ISO 9001:2008

OPC Compliant, PAT Compatible, 21 CFR Part 11 Compliant